|

JaySafe Systems Technical |

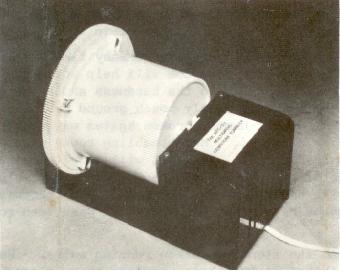

Wessex Impex Ltd ATC Tumbling System |

|

Home Page Tech Index SR BackUp ATC Tumbler Disclaimer User_Agent RJ45 PinOuts Halfords Transit'07 CHY 650 Interstater msodi error RAM memory Sky rcu TowerStat XP from usb |

The ATC Tumbling System Owners Manual : Instructions & Guarantee  Important:

Important:The ATC tumbling system is a technically advanced concept. To obtain, the best results, follow these instructions carefully and disregard normal tumbling manuals. Owners Responsibilities Since Tumblers run 24 hours a day, care and maintenance are important to long life and good performance. Keep the machine clean and free from abrasive grit. Avoid filling or unloading the barrel over the tumbler and disconnect from electrical supply when not in use. Wipe barrel clean prior to tumbling and scrub any accumulated dirt out of the gear surfaces and inside. Never overlead your ATC Tumbler; at no time must more than 5 lbs. of rock be tumbled, equivalent to a maximum combined weight of barrels, rock, water and grit of 7 lbs. (this applies particularly to Add—A—Barrel operation). Operating Procedure 1. Put two or three drops of light mineral oil (such as “Three in One”) on to the bearing surfaces, and especially the steel shaft that holds the small diameter nylon gear that engages the barrel. This lubrication should be done before the machine is run and subsequently every week. 2. Set your ATC Tumbler to high speed by inserting the “low” bearing set in the bearing recesses. (as above). Press them right down, otherwise the drive gears will not engage. Put the barrel into the machine so that the smaller diameter gear is in contact with the main drive gear. 3. Put ½” water into the bottom of your ATC barrel, using the moulded ledge as a guide line for the correct level; next fill the barrel to a maximum three quarters full of rock and put in one ounce (equivalent to 3 heaped teaspoons) of 190 Grit Silicon Carbide. (A special pack of Wessex Impex Grits and Polishes for the ATC Tumbler is available from your Rock Shop). Note the starting weight in your logbook. Due to the bearing spigots that project from the top and bottom of the barrel it is difficult to stand the barrel upright whilst tightening the lid: Stand the barrel on a jam jar or similar object. When assembling the lid it is unnecessary to over tighten the barrel wing nuts: A light firm pressure is all that is necessary to ensure a good watertight fit. Note: It is most important that this Tumbler is not used to tumble stones over 1 oz. in weight and that the average size of stone is about j” diameter, with a fair proportion ofsmaller stones. To break large stones, use a chisel edged rock hammer, and cover the stones with sacking before striking them. Use goggles and gloves for safety. 4. The Rough Grind. Run the tumbler on high speed for two days continuously, then change the grit. Take an old bucket and fill it with water. Take a fine kitchen sieve and empty the dirty contents of the barrel into it, whilst holding it over the bucket of water. Clean the stones by dunking them up and down until they are completely clean and then weigh them. After noting down the new weight in your log book, recharge the barrel as in 3 above. Clean off the rubber “0” ring and the lid by scrubbing them under water, rinse them off under the tap then replace the lid. Do not discard your bucket of dirty water; it will block your drain if you pour it down the sink. Use it for each subsequent washing operation, but take care not to disturb the layer of used grit in the bottom of the bucket. When you have enough, pour off the water, leave it in the open air for a few days to dry and then put in in the dustbin. 5. Repeat your two day rough grinding operation as many times as is necessary to obtain a batch of well rounded stones. Your log book will help you judge the length of time needed, which of course varies according to the hardness and shape of the original stone. Thus water worn beach pebbles (already mostly rough ground by the sea) need only lose about 20% of their starting weight, whilst hammer broken agates may require 40% to 50% weight loss before an acceptable shape is obtained. Most tumbling books recommend a five to seven day rough grind cycle using 60 or 80 grit. Your ATC will complete a rough grind cycle in two days using 100 grit because of its high speed operation. Next select the stones for further work, removing those that are badly cracked, chipped or are otherwise unsuitable. At this point you can add other stones of similar hardness that have been rough ground in other batches. 6. The Medium Grind. Wash the stones in clean running water. Put water into the Tumbler barrel up to the level described in (3) above, replace your selected stones and three heaped teaspoonfuls of medium grit Silicon Carbide. Run for ONE day then rinse out using the same procedure as described in (4) above. Then take the barrel, gasket and lid and give them all a thorough scrub under running water and also rinse the stones under running water. Reload and recharge in the same way then run for FIVE days. If you have a spare barrel or Add-A-Barrel unit in use for medium grind only, the first step mentioned above is not necessary. 7. The Fine Grind. Change the speed of the machine to slow speed by removing the “low” bearings, inserting the “high” bearings, then turning the barrel round so that the larger diameter gear on the lid engages the small drive gear, as below. The fine grind is a repeat of the medium grind in all respects except that four heaped teaspoonfuls of fine Silicon Carbide grit is added at each stage. Again if you have a spare barrel or Add—A—Barrel the first step (one day, then clean out) is not necessary. 8. Polishing the Stones. We strongly recommend use of a spare barrel or (even better) Add-A-Barrel unit for polishing only. If you do not have an Add-A-Barrel you must take steps to remove all traces of grit from the walls of your barrel and this can only be done by polishing in two stages. Clean the rocks, the barrel, lid, gasket under running water. Replace the stones in the barrel and add five heaped teaspoonfuls of a recommended polish such as Tin or Cerium Oxide. If you do not have a full load add polishing pellets to bring the level of the load up to the recommended two thirds to three quarters full. After three days take out and wash the stones being careful not to empty the polish down the drain, scrub the stones, barrel, lid and gasket under running water, discard any broken stones that might scratch the others, refill the barrel as before and then run until you have a good polish (maximum THREE days for quartzes, TEN days for agates). Be careful not to over-polish the softer stones. Your Log Book. Keep a log book to help you identify the contents of each barrel, and to judge the time needed for each material. For example:

Recommended Speeds: Paint a line onto the lid of each barrel, then use your watch to time the revolutions in each minute. (This will vary according to the load). Speeds given are approximate:

Please remember that factors other than speed affect a good finish. Cleanliness, correct polish, no giant stones and don’t mix hardhesses. Also poor quality rough. Read the book “Gem Tumbling & Baroque Jewellery Making” by the Victors for good technical advice. Trouble—Shooting (For Multidrive with or without Add--A—Barrel) (A) Tumbler will not start: no noise Check all electrical connections and fuses, then have an electrician check the motor. If it is unserviceable return the faulty motor to us for replacement. (B) Tumbler will not start: it makes a humming noise Check that nothing is obstructing the drive and see if the gears are jammed together. Adjustments can be made by slightly adjusting the motor position (moving it up and down on the motor mountings). Try turning it by hand to start it. Check that there is no grit in the bearings or in any of the moving parts of the Tumbler. If there is, it must be cleaned out immediately or alternatively the machine should be stripped right down and thoroughly cleaned out. Grit in the bearings will stop any tumbling machine and this is outside the terms of the guarantee. (C) Tumbler runs but is excessively noisy If it is new it needs running in under load (just like your car) for about one week. If the noise level is still too high adjust the meshing position of the gears by loosening off the motor mounting screws and raising or lowering the motor. This adjustment is critical for the correct running of the machine, it is important that one of the gears can be moved very slightly without moving the other (correct backlash). Put a drop of “Three in One” oil on each of the bearing surfaces and check the lubrication in the sleeve bearing through which the idling shaft runs. A whining noise either occurs in this sleeve or between the motor gear and the large idler gear. The gears are correctly set before the machine leaves the factor do not adjust unless it is essential. (D) Tumbler makes a rattling type of noise whilst running Stand the machine on a soft surface that will absorb noise and see if you can eliminate it b pressing the motor mounting cover down on to the body. If this works, insert a thin piece of felt between the vibrating parts. (E) Motor turns but barrel does not Check that your bearings are pushed right down in the slots that hold them. If this does not work remove the barrel and the motor cover then block the transmission by gripping the small drive gear. You will now be able to see if any of the gears are loose on their appropriate shaft. If this is the case the gear in question can be fixed back on again by use of a Cyano—Acrylate adhesive, or Devcon epoxy resin. (F) Barrel leaks Check that all sealing surfaces including the 0 ring are completely clean and are free from grit, sludge and small particles of stone. If the barrel still leaks then the gasket needs replacement. (G) Uneven motor noise This means that the machine is over loaded (i.e. is driving a weight that is too large). Immediately reduce the pay load. (This applies particularly to Add—A-Barrel operation). If the motor still makes an uneven noise, one of the barrels may be jammed very tightly against the gears of the next Add—A-Barrel unit. Remember, overloading the machine invalidates the guarantee. GUARANTEE AND MAINTENANCE Most of the difficulties encountered with these machines result from problems than can be easily rectified by the user. We strongly recommend you obtain a copy of the book “Gem Tumbling and Baroque Jewellery Making” by the Victors. We believe this book to be the finest standard technical manual on tumbling in print today, but the Victor book should be read in conjunction with these instructions which contain specific information on correct speeds, grits and tumbling times for use with this machine. Your lapidary supplier will help you sort out most of your remaining problems. Some problems however are best dealt with by us, but this does involve you in postage costs and delays as well as labour and parts charges when the machine is out of guarantee. After you have read these notes please fill in and send us the Guarantee Registration Form. If we do not have this, the Guarantee is not valid. However we do wish to state that our aim is for you to enjoy your hobby so we are sympathetic to your problems. Our address for return of machines is: Wessex Impex Ltd., Winnall Factory Estate, Winchester, Hampshire, England. This Guarantee is not valid if the machine is over—loaded; you must never run it with more than 5 lbs. pay load of stone or a total weight of stone, barrels, water and grit of 7 lbs. WESSEX IMPEX LTD. 180 DAY GUARANTEE. THIS PRODUCT IS GUARANTEED BY US IN BRITAIN FOR 180 DAYS FROM THE DATE OF SALE. IF YOUR MACHINE DOES NOT FUNCTION PLEASE RETURN THE FAULTY COMPONENT TO US FOR FREE REPLACEMENT. MACHINES RETURNED TO US UNDER GUARANTEE WILL HAVE NECESSARY REPAIRS MADE FREE OF CHARGE, NORMAL MAINTENANCE AND CLEANING WILL BE CHARGED FOR. PLEASE ENCLOSE SUFFICIENT MONEY TO PAY FOR RETURN POSTAGE AND PACKING (40p).

You can also DOWNLOAD this pdf file of the original document. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

Add JaySafe to my favourites. Make JaySafe my Home Page. Send an email to WebSiteMaster with questions or comments about this site. Copyright ? 2001 JaySafe Systems. Last modified: 20 July 2016. |

Visitor No 7871 |